What are the diameters of steel pipes. Spherical parameter in vacuum: nominal pipe bore

As you know, the conditional pipe passage is a parameter that marks the gas and water steel pipes and fittings for them. The parameter is rather strange: with rare exceptions it is not equal to the outer or inner diameter. In this article I want to talk about why the concept of conditional pass is introduced, and what values \u200b\u200bit can take. In addition, I will give some recommendations on how to choose optimal size pipes.

Why is it necessary

First, let's figure out what a conditional pass is and why this parameter is needed.

One of the problems faced by pipeline installers is the problem of compatibility of different pipes with fittings and with each other. The fact is that water and gas pipes, depending on the strength requirements, belong to one of three types:

- lungs;

- ordinary;

- reinforced.

The difference in wall thickness cannot but affect the actual internal diameter. So, for a pipe DN 25 with an external diameter of 33.5 mm, the wall can have 2.8, 3.2 and 4 millimeters, which will give an internal diameter of 27.9, 27.1 and 25.5 mm, respectively. Moreover, all three varieties are fully compatible with pipe thread size 25 mm.

Agree, it will be quite logical to use the same designation for them.

Why is the outer diameter not selected in this quality? Pipes not intended for water and gas pipelines are marked with it. Plumbing and gas pipelines have their own specifics. The fact is that the main parameter of pipes for their installation is throughput directly related to the inner diameter. Which, I recall, varies over a fairly wide range.

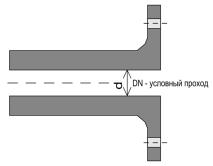

Conditional pass is an internal diameter rounded up or down to the nearest standard value. For shut-off valves, it also indicates compatibility with a correspondingly sized pipe thread.

Designations

The traditional designation of the conditional passage on the domestic shutoff valves is ДУ (from “conditional diameter”). Now, most manufacturers have switched to the naming system adopted abroad and use the DN designation (diametre nominel, nominal diameter). Size can be specified both in millimeters and in English inches (2.54 cm).

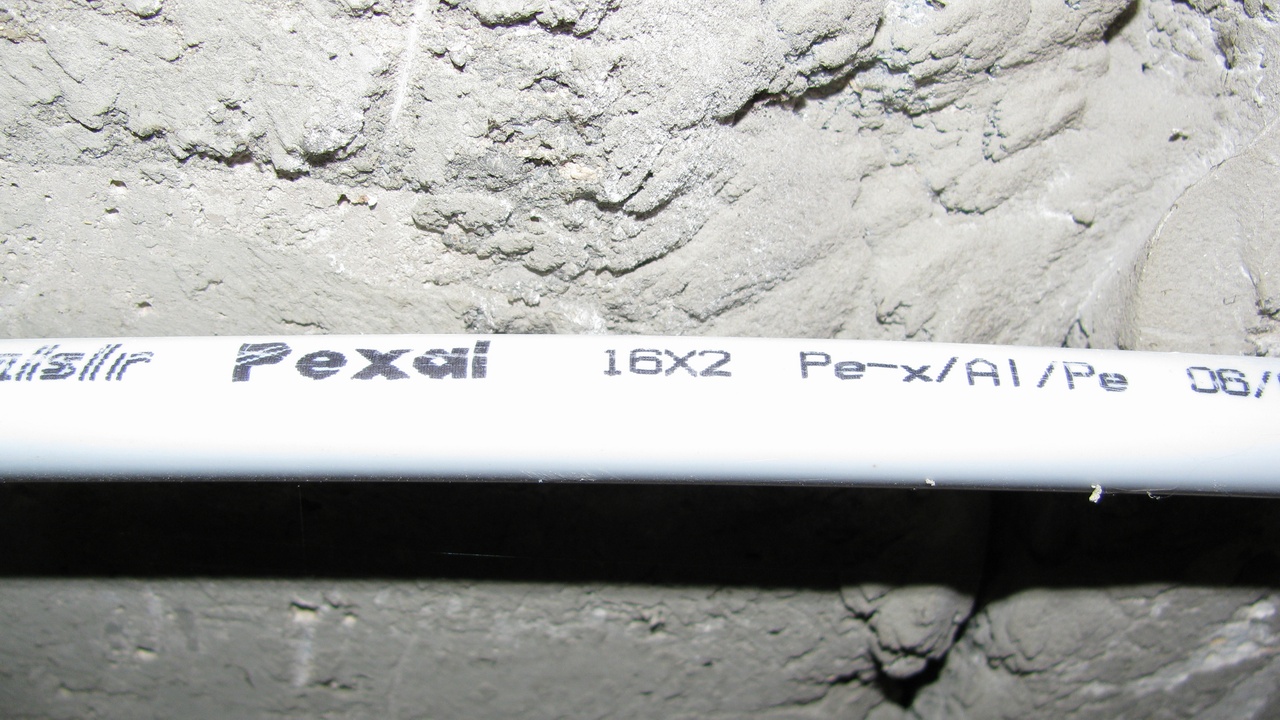

In the photo - a ball valve. The DN in the marking indicates the size of the thread to be connected, PN indicates the working pressure.

Units are never indicated on the marking. Fortunately, visually confusing a 15 mm thread with a 15 inch thread is quite difficult.

Values

So what is it - we figured it out. What are the standard remote control values? And what is the actual outer diameter of the conditional pipe DN 15 or DN 50?

For answers, we will have to dig into the regulatory documentation.

GOST 28338-89

This standard contains a series of conditional pass values. The remote control may be equal to:

| 2,5 | 3 | 4 | 5 | 6 |

| 8 | 10 | 12 | 15 | 20 |

| 25 | 32 | 40 | 50 | 65 |

| 80 | 100 | 125 | 150 | 200 |

| 250 | 300 | 350 | 400 | 450 |

| 500 | 600 | 700 | 800 | 900 |

| 1000 | 1200 | 1400 | 1600 | 1800 |

| 2000 | 2200 | 2400 | 2800 | 3000 |

| 3400 | 4000 |

For hydraulic and pneumatic devices, conditional passages DU 16, DU 63 and DU 160 can be used. The standard also provides for sizes 175, 2600, 3200, 3600 and 3800, but prohibits their use in the production of pipe fittings for general purposes.

GOST 3262-75

The second standard regulates the production of gas and water pipes and contains a list of their actual sizes for each control unit up to 150. We will not use the standards describing the technical conditions for the production of large diameter pipes: hardly a respected reader will encounter them when installing plumbing in their own apartment.

| DN | Outside diameter | Wall thickness mm | ||

| Lungs | Common | Reinforced | ||

| 6 | 10,2 | 1,8 | 2 | 2,5 |

| 8 | 13,5 | 2 | 2,2 | 2,8 |

| 10 | 17,0 | 2 | 2,2 | 2,8 |

| 15 | 21,3 | 2,5 | 2,8 | 3,2 |

| 20 | 26,8 | 2,5 | 2,8 | 3,2 |

| 25 | 33,5 | 2,8 | 3,2 | 4 |

| 32 | 42,3 | 2,8 | 3,2 | 4 |

| 40 | 48 | 3 | 3,5 | 4 |

| 50 | 60 | 3 | 3,5 | 4,5 |

| 65 | 75,5 | 3,2 | 4 | 4,5 |

| 80 | 88,5 | 3,5 | 4 | 4,5 |

| 90 | 101,3 | 3,5 | 4 | 4,5 |

| 100 | 114 | 4 | 4,5 | 5 |

| 125 | 140 | 4 | 4,5 | 5,5 |

| 150 | 165 | 4 | 4,5 | 5,5 |

In plumbing, VGP pipes are used, starting with the size of DN 15 (as water supply and heating pipes).

Steel water supply. Size - DN 15.

Inches and millimeters

The ratio of sizes in inches and millimeters in the marking of plumbing fittings does not obey a clear pattern. Alas, you can’t just multiply the number of inches by 25.4: the result will be far from the standard values \u200b\u200bof the remote control.

But you can remember the table of their correspondence:

| DN (mm) | Remote control (inches) |

| 15 | 1/2 |

| 20 | 3/4 |

| 25 | 1 |

| 32 | 1 1/4 |

| 40 | 1 1/2 |

| 50 | 2 |

And what about others

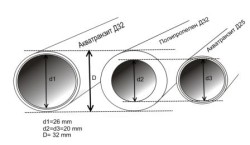

And how are plastic and metal-plastic pipes marked?

The size indicated by the seller is the outer diameter of the pipe. In the marking, in addition to it, there is usually a wall thickness in millimeters.

Payment

Instructions for heating and water supply systems will vary markedly.

Heating

Here, the key parameter is the heat flux that the pipe is able to let through. It can be increased by inner diameter growth (which is disadvantageous, since with its increase the price of a running meter of pipe grows nonlinearly) or coolant speed.

The speed, however, is limited from above by a maximum value of 1.5 m / s: with its further increase, hydraulic noises become difficult to tolerate. In practice, when calculating heating systems, a speed range of 0.4-0.6 m / s is used at all.

For the convenience of the reader, I will include in the article a table of the dependence of the heat flux on the nominal diameter of the pipe.

How to use this table? You just need to select the value of the heat flux closest to your value and find the diameter corresponding to it in the left column.

How to calculate heat flow in your heating system?

- For an autonomous circuit, when calculating the filling, the thermal load is taken equal to the rated power of the boiler;

- Individual sections of the circuit and the supply to are calculated according to the nameplate power of the devices;

- In the absence of technical documentation for them, power can be roughly estimated at the rate of 200 watts per radiator section.

Water supply

An accurate calculation of the throughput of a steel pipe with a known diameter is extremely difficult, because, in addition to the pressure in the water supply, its hydraulic resistance must be taken into account.

And it, in turn, depends on:

- pipe lengths;

- number and angle of turns;

- shutoff and control valves;

- roughness of the pipe walls;

- her service life. Over time, steel pipes become overgrown with rust and lime, which increases their roughness and reduces clearance.

In practice, it is enough for the owner of an apartment or private house to remember a simple rule:

- When the length of the water supply is up to five meters and the number of simultaneously used plumbing fixtures is not more than three, the size is used DN 15;

- With a length of water supply of 5-30 meters and the number of plumbing fixtures used simultaneously up to five, the nominal size of the water supply increases DN 20;

- With a greater length and / or number of toilets and sinks, a steel pipe DU 25 or a plastic pipe equivalent in capacity is used.

Conclusion

I hope that I was able to satisfy the curiosity of the reader. As usual, additional materials can be explored by watching the video in this article. Waiting for your additions and comments. Good luck, comrades!

July 31, 2016If you want to express gratitude, add clarification or objection, ask the author something - add a comment or say thanks!

Any steel pipe, regardless of the application, is characterized by such fundamental values \u200b\u200bas diameter (sometimes internal and external), length and density / wall thickness.

The outer diameter is most often understood as the distance between the outer edges, which depends on several factors, including the same wall thickness, the manufacturer, the method by which the pipe was made and, of course, the field of application.

Introduction

All diameters steel pipeswhen it comes to standards, are determined by GOST in accordance with the type. So it becomes much easier the calculation procedure during installation and preliminary design of the pipeline, if the outer diameter is known. Knowledge of this value can be considered the key to the correct selection of all elements (plugs, tees, transitions, valves). In addition, this value is simply extremely important and indispensable in calculating weight.

It is convenient to enclose the diameter and wall thickness of steel pipes in tables.

Seamless material options

| Cold formed pipe | Hot deformed pipe | ||

| Outer diameter (mm) | Wall thickness (mm) | Outer diameter (mm) | Wall thickness (mm) |

| 23 | 5 | 32 | 3 |

| 26 | 4 | 42 | 3.5 |

| 40 | 5 | 57 | 3.5 |

| 48 | 6 | 76 | 4 |

| 57 | 2.8 | 89 | 3.5 |

| 60 | 4.5 | 108 | 4 |

| 68 | 4 | 133 | 5 |

| 75 | 5 | 146 | 5 |

| 85 | 9 | 159 | 6 |

| 102 | 10 | 168 | 8 |

| 120 | 6 | 219 | 8 |

There is an exception, in this case, which are gas and water pipes, the classification of which is compiled on the basis of such a condition as conditional passage (DN)

Water pipe parameters

| Outer diameter mm | Inches | Conditional pass |

| 10,2 | 1/8 | 6 |

| 13,5 | 1/4 | 8 |

| 17 | 3/8 | 10 |

| 21,3 | 1/2 | 15 |

| 26,8 | 3/4 | 20 |

| 33,5 | 1 | 25 |

| 42,3 | 5/4 | 32 |

| 48 | 3/2 | 40 |

| 60 | 2 | 50 |

| 75,5 | 2 ½ | 65 |

| 88,5 | 3 | 80 |

| 101,3 | 3 ½ | 90 |

| 114 | 4 | 100 |

| 140 | 5 | 125 |

| 165 | 6 | 150 |

The above tables of diameters, wall thicknesses of steel pipes give an idea that, for example, the outer diameter is a value that is determined strictly by GOST, and it is constant. And in order to achieve greater product strength, resort to an increase in wall thickness. As a result, the internal dimensions of the circle differ from the nominal (aka nominal) diameter passage, which, in turn, which is a conditional value, is used in the installation of pipeline elements. This parameter is in conjunction with the clearance parameter. It often happens that the wall thickness of steel pipes is different for the same conditional passage, so it is customary to subdivide them into ordinary ones, with thick and thin walls.

Scope of steel pipes

Each type has its own field of application. So a steel pipe with thin walls is considered universal in its field of application, since it is convenient in processing by a welding machine and good in bending.

Tables with diameters and wall thicknesses of steel pipes and weight are far from exhaustive information. So, in the case of increased demands on such important parameterlike steel pipe strength used seamless pipe with thin walls, which has found wide application in the aircraft industry, the manufacture of machine parts, pipelines and more. Its main advantage, regardless of the conditions in which it will be used, is its large diameter and length, as well as increased strength with a minimum wall thickness.

The steel pipe with thick walls, by and large, is not inferior to the thin-walled in universality and surpasses the previous view in terms of reliability, strength, resistance to high pressures and corrosion.

The given parameters of wall thickness and diameter of steel pipes in the tables are indispensable for calculations and a visual representation of how these characteristics are measured with each other.

Returning to the diameters and scope of the involvement of steel pipes, it can be noted that their use is widespread in the construction sector, in agriculture, the automotive industry, in the food industry, chemical, household and others. Such popularity is primarily due to economic benefits. Important for any steel pipe is both the appearance and the inner diameter. And the main difference between them is that, along with how the inner diameter remains always unchanged, the outer one can vary depending on the wall thickness.

It is diameter that is the basis for dividing products into classes. Knowing the diameter of the steel pipe will allow, for example, to calculate in advance the number of them needed to transport any substance along the highway. Consequently, it becomes possible to determine the load on weak points, on the designed system as a whole and, importantly, the possibility of eliminating them.

It is not difficult to look at tables of diameters and wall thicknesses of steel pipes, especially since they are given above, but it is worthwhile to dwell in more detail on such an important nuance as a variety of diameters. They can be: nominal, conditional (the actual size of the internal parameter of the pipe, measured in millimeters), internal and external - respectively, an important parameter and indicator for the selection of connecting elements and fittings, according to which all steel products are classified. What is characteristic, the diameter of the steel pipe determines the scope of its application.

In the ratio of diameter to wall, the products are divided into the following types: normal, averaged structures, elements with thick walls, products with thin walls, pipes with walls especially thin and pipes with walls especially thick. Pipes are also divided into: profile, water and gas pipes, straight-seam electric welding pipe, seamless hot-deformed pipe and seamless cold-deformed pipe.

Steel pipe strength

As for the strength of the pipe, this property depends on the shape and dimensions of the cross section, since the load that steel pipes can withstand depends on the wall thickness. Therefore, along with all tables of wall thickness and diameters of steel pipes, there are also additional characteristics, including such as strength. The latter is used in pipelines to calculate the allowable external and internal pressure, as well as to calculate the rigidity of the frame in metal structures. In other words, neither a metal structure nor a pipeline can exist without a “correct” section.

So, the geometric parameters of a steel pipe are regulated by a number of GOSTs (normative documents), which specify specific values \u200b\u200b(in millimeters), and also present deviations (permissible) from the mentioned values \u200b\u200b(product length, wall thickness, outer and inner diameters) as a percentage of the regulated dimensions.

Add to bookmarks

Pipe passage features

The most important characteristic of any design is the diameter. It can be conditional, nominal, external and internal. To accurately make a design calculation, taking into account all the necessary characteristics, you need to know a lot about the products used. For this, the existing classification according to size and wall thickness is used. Designers greatly facilitate their work standards governing this value.

What is a conditional pipe passage?

This is an indicator of the nominal parameter that exists to describe the system as a characteristic feature when mounting and connecting to each other various parts (the parts themselves, fittings, and other equipment for the pipeline).

The diameter of the lumen of the pipeline has an approximate value of the conditional passage. It is labeled as, for example, Du 100.

The pipeline throughput during the transition should increase by an amount corresponding to a value from 60 to 100%, it is for this that the corresponding graduation of the conditional passage is calculated. The pipeline capacity will depend on the correctness of the calculation.

In other words, this concept refers to the average product parameter (by clearance). The value is rounded up or down to the standard designation level.

The designation of the passage is as follows: Du. Digits corresponding to the size in millimeters are added to the literal value.

The true level usually does not exactly match (there are rare exceptions) to the size of the structure.

- We give an example. A system with an outer diameter of 159 mm and a wall thickness of 8 mm has a true accurate internal dimension of 143 mm. If the wall thickness is 5 mm, then 149 mm. But, despite the difference, in both cases the passage will be designated as equal to 150 mm.

Standards GOST 28338-89 set the basic parameters of the passage of fittings, fittings and fittings of technological and sanitary fittings to be connected to the fittings.

Inner pipe size

The actual inner diameter of the pipes directly depends on the actual wall thickness.

The dimensions for a water or gas pipeline are determined by this parameter, and the remaining types - in accordance with the outside.

For steel products are characterized (by technological conditions of production) constant values. And due to the fact that for structures designed for operation under high pressure, reinforce the thickness of the walls, this size will differ from the passage. An example of such a difference is the following calculation.

- Outside, the reinforcement parameter is 273 mm with a wall thickness of 9 mm, while the actual internal parameter (excluding tolerances) is 255 mm. But the conditional passage value will be indicated by the closest standard value, that is, 250 mm.

Variety of diameter types

They are classified as follows:

- conditional (Du) - the nominal value of the internal size in millimeters or the rounded digital value in inches;

- nominal (days);

- outer;

- interior.

Since a combined system is often used, a special table of correspondence of diameters, for example, steel products to polymer reinforcement, has been developed for easier and more correct selection.

Suppose if you need to lay a system using only steel structures, then there will be no difficulties. The diameter of steel products is indicated in inches. If you need to connect steel and plastic structures, then, in order not to be mistaken in size, you need to use a special table. This normative document designed to determine the exact match of the inch length of steel parts with plastic. Since the diameter of most plastic structures is indicated in millimeters.

An inch is a unit for measuring distance practiced in several non-metric measuring systems. As usual, the value in inches, equal to one, will correspond to 1/12, or 1/10 feet, depending on the country. Nowadays, an inch value means a value in English inches, equal to 2.54 centimeters.

Why determine the exact size of the systems used

The exact value of the diameter will allow you to calculate the planned volume of the substance to be transported through the pipeline. Knowledge of the characteristics of the parameters of various systems is important both on an industrial scale and at home.

Laying the heating system or repairing it in your home is carried out with a preliminary calculation so that winter does not catch by surprise and all living rooms are heated with high quality and evenly. The recommendations and features described above will allow you to learn more about the parameters of the pipeline. If you have any doubts or difficulties, it is better to consult a specialist.